Reflux drum : Reflux ratio optimization via Reflux drum design

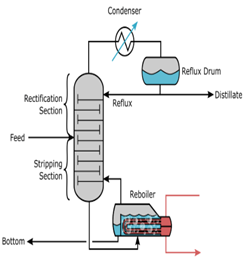

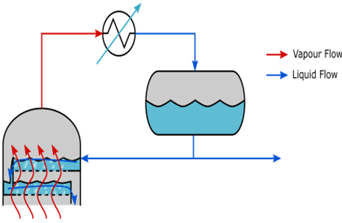

A reflux drum is a horizontal vessel that collects the condensed vapor from the top of the distillation column. From here, part of the liquid is sent back into the column as reflux, and the rest is drawn off as the distillate product.

While it may seem like a simple storage tank, the design of the reflux drum plays a big role in how efficiently the column operates. One of the key factors it influences is the reflux ratio — the balance between how much liquid is returned to the column versus how much is taken out.

We’ll explore how smart design choices for the reflux drum can help optimize the reflux ratio and improve the overall performance of a distillation system.

Understanding Reflux Ratio

The reflux ratio (RR) is defined as:

RR = Reflux Flow Rate / Distillate Product Flow Rate

This ratio governs how much of the condensed overhead vapor is returned to the column versus how much is withdrawn as the distillate product.

- A higher reflux ratio enhances separation but at the cost of higher energy consumption.

- A lower reflux ratio saves energy but may compromise product purity.

The challenge: Strike a balance — minimize energy input while maintaining product specifications.

The Role of Reflux Drum in Reflux Ratio Optimization

The reflux drum, also known as the overhead accumulator, is located right near the condenser. It collects condensed vapors from the top of the distillation column and allows phase separation between liquid and any remaining vapor.

But beyond this basic role, its design profoundly influences how precisely and efficiently the reflux ratio can be controlled.

Key Design Elements That Impact Reflux Ratio Optimization

Drum Sizing: The Buffer Against Instability

A correctly sized drum (typically allowing 5–10 minutes of liquid holdup) provides:

- Flow dampening: Stabilizes fluctuations in feed and product rates

- Process flexibility: Eases transitions during load changes

- Control system responsiveness: Prevents oscillations in flow and level loops

Impact: Consistent reflux and distillate flows → stable and optimized RR.

Level Control Precision

The drum must allow accurate and reliable level measurement and control, which regulates the flow of:

- Reflux back to the column

- Distillate to storage or downstream units

Impact: Fine-tuned level control ensures a precise reflux-to-product ratio under varying conditions.

Phase Separation Quality: Reflux Purity Matters

The drum should effectively separate residual vapors from liquids. Design features that enhance vapor-liquid disengagement are :

- Demister pads

- Vane-type mist eliminators

- Baffles or coalescers

Impact: A clean, stable liquid phase returned as reflux → consistent RR effect and product quality.

Thermal Behavior: Subcooling and Heat Control

Sometimes, reflux is subcooled to control the internal column hydraulics or manage energy loads. The reflux drum must be designed to:

- Handle partial or total condensation

- Accommodate thermal expansion

- Avoid unwanted vaporization

Impact: Thermal consistency = stable vapor-liquid equilibrium = controlled RR impact.

Instrumentation & Control Integration

A reflux drum is more than a vessel — it’s an interface point for sensors, transmitters, and valves. Proper nozzle placement and instrumentation access enable:

- Real-time monitoring of temperature, level, pressure

- Implementation of advanced control strategies (cascade, ratio control)

- Smooth response to plant dynamics

Impact: Enhances automation of RR control — critical for large-scale or multicomponent systems.

At a Glance: Reflux Drum Design vs. Reflux Ratio Optimization

| Design Feature | Influence on Reflux Ratio Optimization |

| Sizing & Holdup Time | Stabilizes flow rates and process dynamics |

| Level Control Range | Maintains precise reflux-to-product split |

| Internal Separators | Ensures clean phase separation and consistent reflux purity |

| Thermal Design | Prevents sub-cooling swings or vapor lock issues |

| Instrumentation Access | Enables accurate feedback and responsive control implementation |

Real-World Perspective

In large-scale distillation systems, like crude oil refining, petrochemicals, and fine chemicals, even a 1% improvement in energy efficiency or separation performance can lead to substantial cost savings and reduced environmental impact.

By optimizing the reflux drum design:

- Energy efficiency improves

- Product purity becomes more consistent

- Column hydraulics stabilize

- Control systems operate with minimal intervention

Conclusion

As chemical processes aim for greater efficiency, sustainability, and control, the reflux drum deserves attention not just as a vessel, but as a strategic design element that directly influences column performance.

The reflux drum may look like a simple vessel, but it plays a key role in how well a distillation column works. A good design helps keep the reflux ratio steady and efficient, which saves energy and improves product quality. By focusing on the reflux drum’s size, controls and layout, whole separation process can be made more reliable and cost-effective.