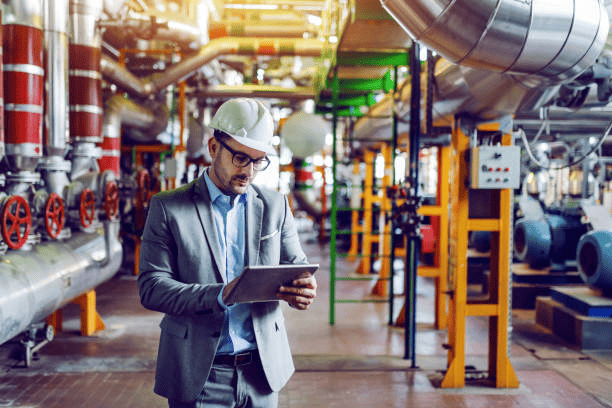

Steady State Simulation

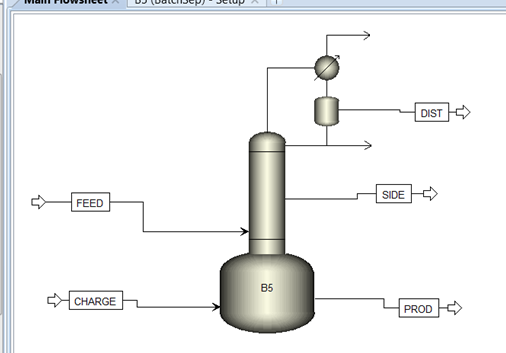

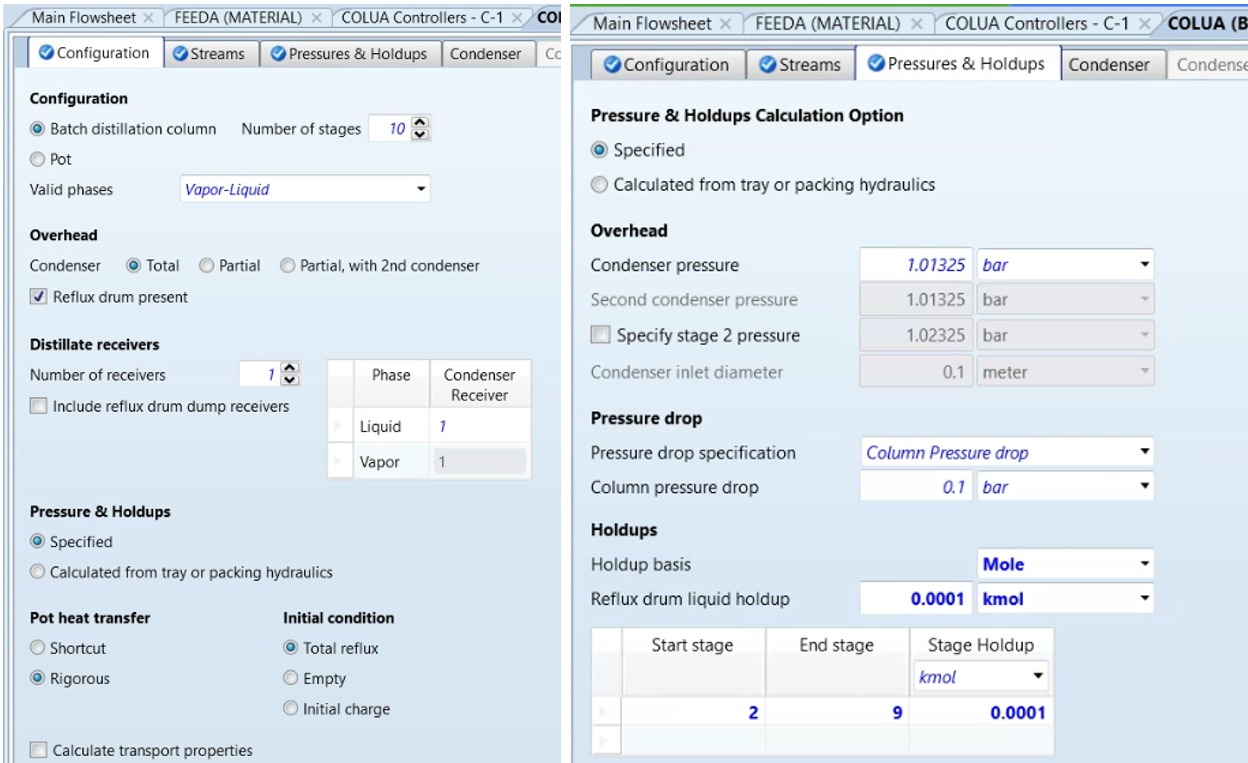

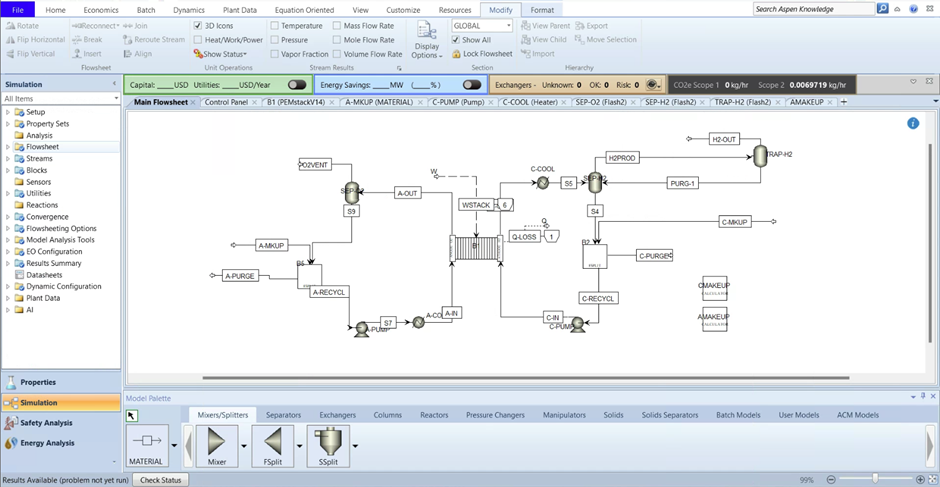

ChemKlub provides steady-state simulation services to model industrial processes under stable, non-changing conditions. This service is crucial for designing, optimizing, and troubleshooting various process units, ensuring maximum efficiency and reliability.

Applications: Commonly applied in refineries, chemical production, and energy optimization. ChemKlub uses steady-state simulation to assist in process validation, equipment sizing, and energy efficiency analysis.