Mastering Distillation in Aspen Plus an Industrial Approach

Introduction

Distillation is a fundamental process in the chemical industry, essential for separating components based on boiling points. Aspen Plus, a leading process simulation software, provides engineers with powerful tools to design, optimize, and troubleshoot distillation systems effectively.

Understanding Distillation in Aspen Plus

Aspen Plus offers comprehensive capabilities for simulating various types of distillation processes, from simple binary separations to complex multicomponent systems. Its robust features allow for detailed modeling of column operations, facilitating better design and operational decisions.

Key Features of Aspen Plus for Distillation

- Rigorous Thermodynamics: Aspen Plus includes an extensive library of thermodynamic models, ensuring accurate predictions of vapor-liquid equilibria. This is crucial for reliable distillation simulations, allowing users to select models that best represent the interactions of components in their specific systems.

- Column Design Tools: The software provides built-in tools for designing and rating distillation columns. Engineers can simulate both tray and packed columns, adjusting parameters such as tray efficiency and packing type to optimize separation efficiency.

- Optimization Capabilities: Aspen Plus excels in optimizing distillation operations. Users can modify reflux ratios, feed conditions, and column configurations to achieve desired separation outcomes while minimizing energy consumption. The software’s optimization algorithms help identify the best operating conditions for maximum efficiency.

Columns in Aspen Plus

Aspen Plus features two main types of columns for distillation:

Shortcut Calculation Columns:

- DSTWU: Used for preliminary design calculations of single-feed, two-product distillation columns. It estimates minimum reflux ratio, number of stages, and optimal feed stage location using methods like Underwood and Fenske.

- Distl: Simulates multistage, multicomponent columns and calculates product composition using Edmister’s method. It is useful for quick simulations with partial or total condensers.

- SCFrac: Designed for complex columns with multiple products, this column simulates sections with constant relative volatilities and minimal liquid flow between sections.

Rigorous Calculation Columns:

- RadFrac: A versatile model for simulating all types of multistage vapor-liquid fractionation, including ordinary distillation, absorption, and extractive distillation. It can handle two-phase and three-phase systems.

- MultiFrac: Suitable for complex interconnected multistage fractionation units, supporting various operations like side strippers and pump arounds.

- PetroFrac: Specifically designed for petroleum refining processes, capable of simulating operations such as atmospheric crude units and vacuum units.

Column Hydraulic Profile in Aspen Plus

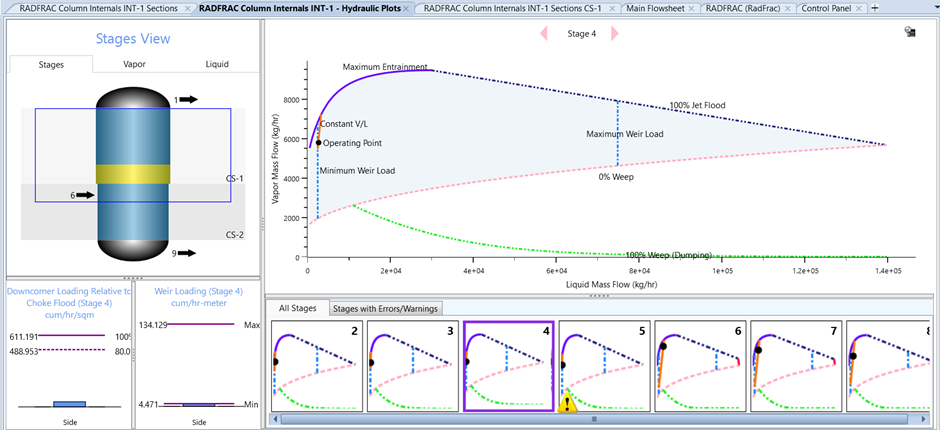

Understanding the hydraulic performance of a distillation column is crucial for optimizing its operation. The hydraulic profile in Aspen Plus provides detailed insights into parameters like vapor and liquid mass flow, flooding points, and weeping limits.

This visual representation helps engineers identify the operating point of the column relative to critical hydraulic limits, such as maximum entrainment and weir loading. By analyzing these profiles, users can optimize column performance, prevent operational issues like flooding or weeping, and ensure efficient separation.

Applications in Industrial Projects

In industrial settings, Aspen Plus is invaluable for process design and optimization:

Process Design: Engineers use Aspen Plus during the design phase to simulate potential distillation setups, allowing selection of the most suitable configuration based on process requirements and constraints.

Energy Integration: The software facilitates energy integration within distillation systems, identifying opportunities to recover waste heat and reduce overall energy consumption, enhancing process sustainability.

Troubleshooting: Existing distillation units often face challenges such as capacity limitations. Aspen Plus enables accurate modeling of these units, identifying bottlenecks and suggesting modifications to enhance performance and increase throughput.

Chemklub India Pvt. Ltd Services

Chemklub India offers comprehensive services:

Process Monitoring and Troubleshooting: Utilizing Aspen Plus & other simulation tools for real-time monitoring, Chemklub India helps to identify and solve operational issues in processes, ensuring optimal performance and minimizing downtime.

Process Modeling and Simulation: Offering advanced simulations for process optimization, Chemklub India assists in modeling complex processes, providing insights that lead to improved efficiency and cost savings.

Training Programs: Chemklub India provides training in Aspen Plus and other simulation tools, enhancing the skills of process engineers. our training programs are tailored to industry needs, ensuring that engineers can effectively use Aspen Plus for design, optimization, and troubleshooting.

Conclusion

Aspen Plus is a powerful tool for engineers working on distillation processes in the chemical industry. Its comprehensive simulation capabilities, rigorous thermodynamics, and optimization tools make it essential for designing efficient and cost-effective distillation systems. By integrating expert services from Chemklub India, companies can enhance operational efficiency and achieve better product quality.

Call to Action

For those looking to optimize their distillation processes, Aspen Plus offers unparalleled capabilities. Contact our team today for expert guidance on maximizing your plant’s performance using this advanced simulation software.