Liquid Management on Trays: The Art of Downcomer Sizing and Flooding Prevention

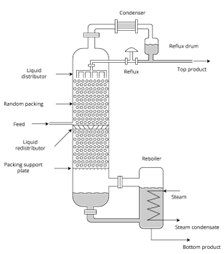

In any distillation or absorption column, efficient liquid management is just as important as vapor distribution. At the center of this hydraulic balance lies the downcomer, a seemingly simple channel, but one that plays a decisive role in column performance.

A well-designed downcomer ensures that liquid flows smoothly from tray to tray without disturbing vapor profile. However, improper sizing or design can lead to conditions like flooding, reduced efficiency, and even column shutdowns.

Understanding the principles behind downcomer sizing, the mechanisms of tray flooding, and the modern innovations will help engineers maximize column reliability and throughput.

Understanding the Downcomer’s Role

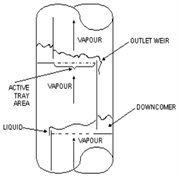

Downcomers are vertical or inclined passages that carry liquid from one tray to the next lower tray in a column.

An ideal downcomer must:

- Allow liquid to flow freely without backup.

- Prevent vapor from flowing into the downcomer.

- Minimize liquid holdup and residence time.

- Maintain mechanical strength and reliability under process conditions.

Fundamentals of Downcomer Sizing

Why Sizing Matters ?

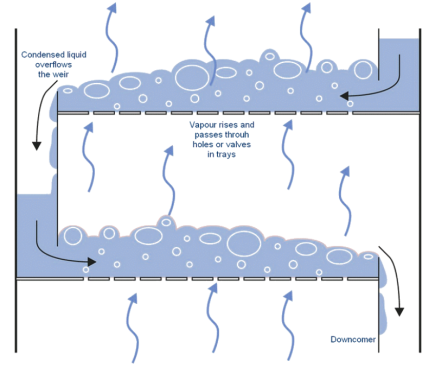

Effective downcomer sizing balances liquid load, operating pressure, and vapor-liquid interaction. Poor sizing can cause major operational inefficiencies.

If the downcomer is too small, liquid will accumulate on the tray, causing a rise in tray liquid height and eventual flooding.

If the downcomer is too large, it reduces the active tray area available for vapor-liquid contact, lowering efficiency.

Effective downcomer sizing balances liquid load, operating pressure, and vapor-liquid interaction. Poor sizing can cause major operational inefficiencies.

Key Design Factors:

- Cross-Sectional Area (Aₑ): Typically 10–20% of the tray area.

- Liquid Velocity: Ideally 0.3–0.5 m/s to prevent excessive entrainment.

- Residence Time: Should allow smooth drainage (commonly 3–5 seconds).

- Clearance Under Downcomer: Must prevent backup due to hydrostatic head.

Design Tip: Increasing downcomer area improves liquid handling but reduces active vapor-liquid contact area — a critical trade-off in high-capacity operations.

Recognizing and Managing Flooding

Flooding in trays can result from excessive vapor velocities, improper liquid handling, or poor downcomer design, which further affects the efficiency.

Signs of Flooding

- Sharp increase in tray pressure drop

- Loss of tray efficiency

- Liquid carryover onto trays above

- Column vibration or instability

Common Causes

- Undersized downcomers

- Excessive vapor traffic

- Tray deck weeping or entrainment

- Maldistribution of liquid flow

Prevention Strategies

- Use multiple downcomers for high liquid rates.

- Opt for sloped or scalloped downcomer designs.

- Model vapor-liquid traffic carefully during design.

- Allow for operational flexibility with adjustable weirs.

Innovations in Downcomer Technology

Modern tray designs incorporate advanced downcomer technologies to enhance capacity and reduce flooding risks:

- High-capacity trays with specially designed inlet and outlet zones

- Caged downcomers that control vapor intrusion

- Multiple downcomer systems to divide large liquid loads

- CFD modeling for accurate prediction of liquid flow patterns

Cutting-edge designs achieve 30–50% higher capacities without compromising efficiency — a significant advantage in retrofit projects.

Conclusion

In tray design, liquid management starts with the downcomer.

Proper sizing and thoughtful engineering can drastically enhance column reliability, throughput, and product purity.

- Design for smooth, unrestricted flow.

- Balance area between vapor and liquid path.

- Prepare for operational variability.

- Innovate when standard designs fall short.