Internals (vapour distributers, chimney trays): Vapour distribution internals; Uniform flow is the key

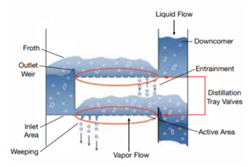

In mass transfer equipment such as distillation, absorption, and stripping columns, the efficient interaction between vapour and liquid phases governs the performance and economics of the process. One important yet often overlooked contributor to efficiency is the vapor distribution internals—specifically, vapour distributors and chimney trays. These internals play an important role in ensuring uniform vapor flow, which is essential for consistent and effective mass transfer.

Why Vapour Distribution Matters ?

Vapour entering a column rarely arrives evenly distributed. It often comes from a single nozzle or a side entry line, leading to maldistribution, if not corrected. Uneven vapour flow can cause:

- Channeling and poor contact between phases

- Reduced tray or packing efficiency

- Higher pressure drop

- Operating instability

That’s where vapour distribution internals come into play.

Vapour Distributors – Types and Functions

Vapour distributors are installed below the first contacting device (tray or packed bed) and ensure that vapour is spread evenly across the entire cross-section of the column. Several designs are used depending on process conditions.

1. Pipe-Arm Distributors

- Comprise radial arms with perforations or slots

- Ideal for large diameter columns

- Easy to install and maintain

- Suitable for moderate to high vapour loads

2. Perforated Plate Distributors

- Simple flat plates with multiple holes

- Provide uniform distribution with minimal design complexity

- Require adequate pressure drop (~10–20 mm H₂O) for even flow

- Good for small to medium loads and column diameters

3. Trough-Type Distributors

- Contain parallel troughs with side holes or slits

- Deliver vapour in multiple streams across the column

- Effective under varying load conditions

- Require higher precision in design and fabrication

4. Bubble Cap Distributors

- Use bubble caps to direct vapour upward through liquid

- Used in special cases where fine control or specific flow patterns are needed

- Help prevent back-mixing and liquid entrainment

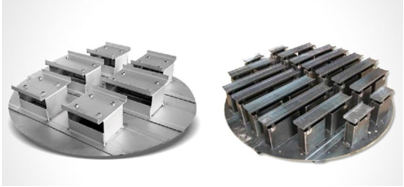

5. Grid-Type Distributors

- Metal grids with evenly spaced vertical risers or jets

- Provide highly uniform vapour flow

- Common in packed towers for fine chemicals and specialty separations

6. Cross-Partition Distributors

- Use cross-like plates to divide the column into symmetrical zones

- Enhance symmetrical flow patterns

- Often used in conjunction with other distribution systems

Chimney Trays – Designs and Purposes

Chimney trays serve as liquid collection and redistribution devices, often used between packed beds or above feed and draw stages. Their core roles include:

- Separating vapour and liquid phases

- Collecting and redistributing liquid uniformly

- Preventing direct vapour bypass from lower beds

1. Conventional Chimney Trays

- Flat deck with vertical risers (chimneys)

- Vapour flows through chimneys and liquid flows over the tray

- Often combined with downcomers or side draw lines

2. Sealed Chimney Trays

- Chimneys are sealed with caps or covers

- Prevent vapour entrainment into the liquid draw-off

- Useful when specific liquid purity is required or vapour contamination must be avoided

3. Vapour-Liquid Separators (VL Trays)

- Function like mini-separators

- Designed to disengage entrained vapour from liquid

- Allow for precise control over phase flows in complex columns

4. Integral Draw-Off Trays

- Include nozzles or troughs for external liquid draw

- Used for intermediate product withdrawal

- Combine liquid redistribution with product handling

5. Redistributor Chimney Trays

- Installed between packed beds to redistribute both liquid and vapour

- Equipped with spray nozzles or troughs above the next packing

- Essential in tall packed columns for staged equilibrium

Design and Engineering Best Practices

- CFD Modeling: Modern designs often use Computational Fluid Dynamics to simulate vapour flow and optimize distributor geometry.

- Minimum Pressure Drop: Ensure vapour distributors create a pressure drop sufficient to overcome entry maldistribution (~10–20 mm H₂O).

- Mechanical Strength: Internals must withstand operational stresses, especially during startup and shutdown.

- Accessibility: Distributors and chimney trays should be accessible for inspection and maintenance.

- Corrosion Resistance: Material selection should match process fluids and temperature.

Industrial Case Example

In an olefin recovery unit, revamping the vapour distributor and adding a chimney tray between packed beds led to:

- 12% increase in product purity

- 10% improvement in column capacity

- 30% reduction in pressure drop

- Enhanced startup stability and reduced oscillations

This highlights how minor improvements in internals can bring significant gains in overall performance.

Conclusion

Vapour distributors and chimney trays ensure that every square centimeter of tray or packing surface is properly utilized. They are the silent enablers of separation efficiency, throughput reliability, and energy economy.

When designing or upgrading a column, don’t just focus on the packing or trays—focus on the vapour distribution. Because when it comes to vapour distribution, uniformity isn’t optional, it’s the key.