How to Choose the Right Reactor Shell Material: Tackling Temperature and Pressure Head-On suggest

When it comes to building a reactor—whether for chemical processing, power generation, or high-pressure experimentation—one question can make or break the system: What material should the reactor shell be made of?

This isn’t just a technical decision—it’s a safety, performance, and cost-defining one. In this blog, we’ll break down how temperature and pressure play a major role in choosing the right shell material for your reactor, and what materials perform best under different conditions.

🔥 Temperature: The Heat Is On

Reactor environments often reach extreme temperatures. Choose the wrong material, and you risk warping, cracking, or even catastrophic failure.

Here’s what to keep in mind:

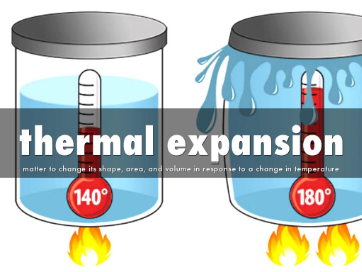

- Thermal Expansion

Materials expand when they heat up. A poor choice can lead to distortion or stress on joints and connections.

- Creep Resistance

At high temps, materials can slowly stretch under pressure. You need a material that holds its shape over time.

- Thermal Fatigue

Repeated heating and cooling can weaken even the strongest materials. Your shell needs to survive these cycles.

Top Performers for High Heat:

- Stainless Steel (304, 316) – Good all-rounders with decent heat resistance

- Inconel – Super tough in high-heat, high-pressure conditions

- Hastelloy – Excellent for corrosive, high-temp situations

- Titanium Alloys – Strong, lightweight, and heat-tolerant

💥 Pressure: Standing Up to the Stress

Reactors often work under serious pressure. Materials must not only hold up, but stay reliable over the long haul.

What to consider:

- Tensile and Yield Strength

Can the material handle the internal pressure without deforming?

- Wall Thickness vs. Pressure

Higher pressure usually means thicker walls—so the material needs to remain practical for construction and heat transfer.

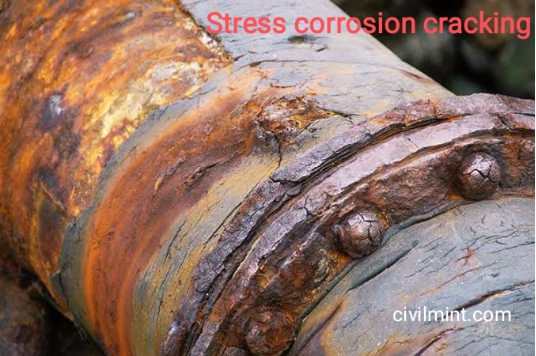

- Stress Corrosion Cracking (SCC)

When stress and corrosion team up, bad things happen. Choosing the right alloy helps avoid it.

Top Choices for Pressure Resistance:

- Carbon Steel – Affordable and strong for moderate conditions

- Chromium-Molybdenum Alloys (2.25Cr-1Mo) – Great for high-pressure, high-temperature scenarios

- Maraging Steel – Known for high strength and toughness

🌡️ Pressure + Temperature = Material Stress Test

When your reactor runs both hot and high-pressure, you need the best of both worlds:

- High creep resistance

- Excellent fatigue strength

- Resistance to chemical attack

Best in Class Materials:

- Nickel-Based Alloys – Think Inconel or Monel for extreme environments

- Refractory Metals – Molybdenum and tungsten are champs in ultra-high temps

🏭 Real-World Applications

Different industries call for different shells:

- Nuclear Reactors – Use carbon steels with stainless linings to balance strength and corrosion resistance

- Petrochemical Plants – Often rely on chrome-moly steels to handle rough fluids and high pressures

- Aerospace Reactors – Lean toward titanium and advanced alloys for strength-to-weight performance

🧠 Final Thoughts

Choosing a reactor shell material isn’t just about picking something strong—it’s about matching the material to the demands of your process. Take the time to understand your pressure and temperature requirements, and you’ll end up with a reactor that’s safe, efficient, and built to last.