Electrolytic Hydrogen: The Key to Green Ammonia Production

In our first blog, we introduced the concept of Green Ammonia, a sustainable alternative to traditional

ammonia that can reduce carbon emissions across multiple industries. A crucial part of the green

ammonia process involves generating green hydrogen—hydrogen produced using renewable energy

sources. This blog will take a closer look at how electrolytic hydrogen is produced, its significance in

the green ammonia process, and its broader applications in the energy transition.

What is Electrolytic Hydrogen?

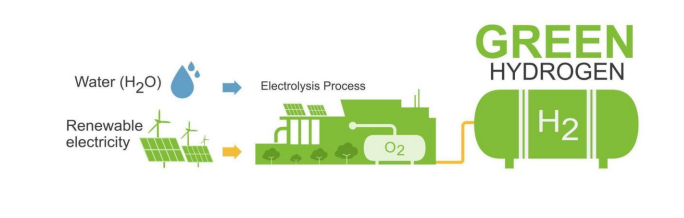

Electrolytic hydrogen refers to hydrogen that is produced by splitting water (H₂O) into hydrogen (H₂)

and oxygen (O₂) using an electrical process called Electrolysis. When this process is powered by

renewable energy (such as wind or solar), the hydrogen produced is carbon-free, making it “green”

hydrogen.

In the context of green ammonia production, this hydrogen is combined with nitrogen (from the air)

in the Haber-Bosch processto form ammonia. The key benefit of electrolytic hydrogen is that it allows

the production of ammonia without relying on fossil fuels, drastically reducing the carbon footprint

of industries such as agriculture and energy

The Process of Electrolysis

Electrolysis is a straightforward process that involves using electricity to break water molecules into

their basic components—hydrogen and oxygen. Here’s how it works:

- Renewable Energy Input: The first step is generating electricity from renewable energy sources,

like wind turbines or solar panels. This clean energy powers the electrolyzer. - Water Splitting: Inside the electrolyzer, water is split into hydrogen and oxygen. This reaction

occurs when electricity is passed through water, resulting in hydrogen at the cathode and oxygen at

the anode. - Green Hydrogen: The hydrogen produced in this process is stored or used immediately for

industrial purposes, such as ammonia production. This is where electrolytic hydrogen becomes crucial

for making the entire process carbon-neutral.

The real innovation lies in using zero-emission electricity to power this process. Since no carbon

dioxide is emitted during electrolysis, it is seen as a cornerstone of future decarbonization efforts

Types of Electrolyzers

There are three main types of electrolyzers used in hydrogen production

- Alkaline Electrolyzers: These are the most commercially mature. They use a liquid alkaline solution

as the electrolyte to conduct ions between the two electrodes. - Proton Exchange Membrane (PEM) Electrolyzers: These use a solid polymer as an electrolyte and

operate at a higher efficiency than alkaline electrolyzers. They are gaining popularity for their

flexibility and rapid response times, making them ideal for renewable energy applications. - Solid Oxide Electrolyzers (SOE): These operate at high temperatures and are still in the research

and development phase. They offer the potential for even higher efficiencies, particularly when paired

with industrial waste heat.

Electrolytic Hydrogen and Its Role in Green Ammonia

Electrolytic hydrogen is essential for green ammonia because it allows the replacement of fossil fuel derived hydrogen with a carbon-free alternative. - Traditionally, hydrogen production for ammonia

involves natural gas in a process called steam methane reforming (SMR), which emits a significant

amount of CO₂. By switching to electrolytic hydrogen powered by renewables, green ammonia

production eliminates these emissions.

Challenges and Opportunities

Although electrolytic hydrogen presents enormous potential, several challenges must be addressed

for its widespread adoption:

- High Costs: Currently, producing hydrogen via electrolysis is more expensive than traditional

methods using fossil fuels. However, with advances in technology and decreasing costs of renewable

energy, this gap is expected to narrow. - Infrastructure Development: The infrastructure required for large-scale hydrogen production,

storage, and distribution is still in the early stages of development, especially for industries that rely

on green hydrogen. - Efficiency: While electrolysis is relatively efficient, improving its energy efficiency remains a key area

of research. Enhancing the efficiency of electrolyzers and scaling up their production will be essential

to making green hydrogen economically viable.

The Future of Electrolytic Hydrogen

Electrolytic hydrogen, when combined with renewable energy, holds the promise of transforming not

only the ammonia industry but also multiple sectors that rely on carbon-intensive processes. As the

global community continues to prioritize net-zero emissions by mid-century, green hydrogen will play

a central role in achieving these climate goals.

Conclusion

Electrolytic hydrogen is a game-changer in the global pursuit of sustainability. By producing hydrogen

in a clean, carbon-free manner, it enables the creation of green ammonia and decarbonizes a wide

range of industries. As technology advances and renewable energy becomes more widely available,

electrolytic hydrogen will help pave the way toward a future with cleaner energy and fewer emissions.

In the next blog, we will dive into the sustainable ammonia synthesis and explore the challenges

and breakthroughs surrounding green ammonia production on an industrial scale.

— Feel free to leave your comments or questions below. Stay tuned for more insights into the future

of green energy