Digital Twin and AI: The Future of Real-Time Optimization

In today’s chemical industry, optimizing processes in real time is no longer a luxury—it’s a necessity. From rising raw material costs to decarbonization targets and the push for 24/7 uptime, manufacturers are under pressure to produce more, waste less, and maintain reliability. Traditional control systems, though robust, lack the adaptability and foresight required in modern operations.

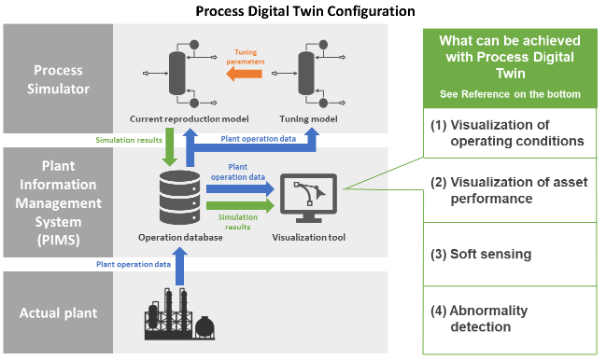

Enter the Digital Twin—a dynamic, virtual model of physical assets—and Artificial Intelligence (AI), which brings a new dimension of learning, prediction, and automation. Together, they represent a transformative leap in process optimization, enabling plants to shift from manual, reactive decisions to automated, predictive insights.

There are three maturity levels of Digital Twins:

- Descriptive Twins visualize and monitor real-time operations.

- Predictive Twins simulate future outcomes under different conditions.

- Prescriptive Twins recommend or even execute optimal actions automatically.

🧠 Artificial Intelligence: The Brain Behind the Twin

While the Digital Twin provides structure and simulation, AI adds intelligence—extracting meaning from vast data streams, recognizing patterns, and learning from operational behavior. This includes:

- Supervised Learning for quality or yield predictions.

- Unsupervised Learning for anomaly detection or process clustering.

- Reinforcement Learning for control optimization and autonomous decision-making.

- Hybrid Modeling where first-principles meet data science, blending physics-based rigor with AI adaptability.

AI essentially allows the Digital Twin to not just reflect what’s happening, but to anticipate what will happen—and why.

⚙️ How Real-Time Process Optimization Works

Real-time optimization (RTO) in chemical plants is a multi-layered system that leverages AI and Digital Twin models to adjust operating conditions on the fly, without disrupting ongoing production.

🔧 Core Architecture:

- Data Acquisition

- Sourced from DCS/PLC systems, field instruments, analyzers, and IoT platforms.

- Data is cleaned and validated to feed models in real time.

- Modeling Layer

- Includes kinetic models (e.g., for reactors), thermodynamic models (e.g., for distillation), and data-driven AI algorithms.

- Digital Twins may simulate thousands of operating scenarios to find optimal paths.

- Optimization Engine

- Applies AI-based or mathematical algorithms (NLP, MPC, genetic algorithms) to determine best setpoints and actions.

- Constraints like safety, equipment limits, and environmental compliance are included in real time.

- Execution and Feedback

- The optimizer sends decisions to APC systems or control layers.

- Continuous feedback allows the model to self-correct and improve over time.

🏭 Where It’s Making a Difference: Applications Across Units

Digital Twin + AI optimization is being successfully applied in several key areas of chemical manufacturing:

- Distillation Units

- Predict column performance under changing feedstocks.

- Optimize reflux ratio, reboiler duty, and tray temperatures to cut energy costs.

- Reactors (CSTRs, PFRs)

- AI models forecast conversion, selectivity, and product yields.

- Optimize feed ratios and temperature profiles for safety and profitability.

- Heat Exchanger Networks

- Digital Twins monitor fouling trends and optimize cleaning schedules.

- AI predicts temperature drop anomalies and preemptive maintenance needs.

- Utility Systems (Steam, Water, Air, Power)

- Balance load and demand with AI-based forecasts.

- Reduce peak energy charges through dynamic scheduling.

- Environmental Monitoring

- Predict NOx/SOx emissions based on operating conditions.

- Automatically adjust combustion or scrubbing systems to maintain compliance.

📊 Benefits Beyond the Control Room

Adopting Digital Twin and AI technologies leads to tangible business value:

- Increased Throughput: Push the limits safely without risking bottlenecks.

- Energy Savings: Reduce steam, fuel, and electricity consumption through better setpoints.

- Proactive Maintenance: Predict equipment failure before it happens.

- Fewer Unplanned Shutdowns: Improve uptime and plant reliability.

- Operational Agility: React faster to market and feedstock changes.

⚠️ Technical and Organizational Challenges

Despite the promise, implementation isn’t plug-and-play. Key challenges include:

- Data Integrity: Poor-quality data undermines AI training and model accuracy.

- Model Maintenance: Digital Twins require recalibration as processes drift or assets age.

- Legacy Systems: Integration with existing DCS/APC platforms can be complex.

- Cybersecurity: Real-time data exchange introduces new risk vectors.

- Change Management: Operators and engineers must trust and adopt AI-driven insights.

🔮 Looking Ahead: A Self-Optimizing Plant

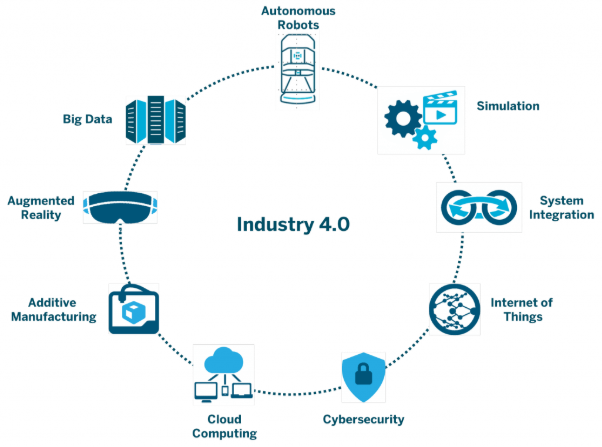

The future plant is autonomous, resilient, and learning-enabled. Advances in cloud computing, edge analytics, and federated learning will further scale these technologies. Imagine:

- Digital Twins running at the edge, adjusting valve positions or setpoints in milliseconds.

- Self-learning controllers that improve every production cycle.

- Plant-wide optimization across units, not just individual assets.

Conclusion

Digital Twins and AI are redefining the boundaries of what’s possible in chemical process optimization. By fusing physics-based models with real-time data and intelligent algorithms, they provide a dynamic, accurate, and actionable view of plant operations. In doing so, they enable chemical producers to optimize performance continuously, reduce environmental impact, and stay competitive in an increasingly digital world.