Cost Reduction Strategies in Green Ammonia Production

In the previous blog, we explored the development of green ammonia infrastructure by analyzing key

projects like HyNetherlands, Australia’s AREH, and Saudi Arabia’s NEOM. These case studies

showcased various approaches to integrating renewable energy with ammonia production,

emphasizing the importance of building dedicated infrastructure for the electrolysis of water,

ammonia synthesis, and distribution networks.

To follow up on that, we will now explore cost reduction strategies in green ammonia production,

focusing on how the industry is addressing economic challenges to make green ammonia more

commercially viable.

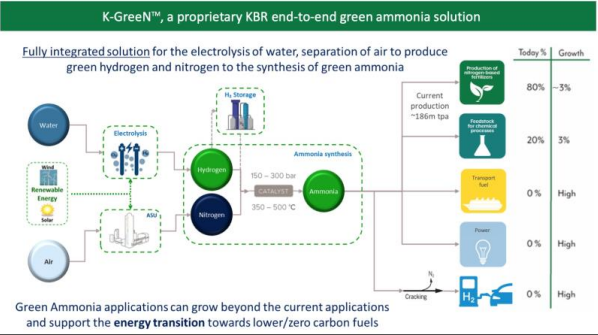

The global transition to green ammonia is being driven by its potential to decarbonize multiple

industries, from fertilizers to energy storage and shipping. However, one of the biggest hurdles to

mass adoption is the high cost of production. Green ammonia, produced by synthesizing hydrogen

from renewable energy sources and nitrogen from the air, is considerably more expensive than

traditional ammonia, which relies on natural gas.

To close this cost gap, innovators and governments are exploring various cost reduction strategies.

This blog will delve into key strategies and provide case studies to illustrate how different projects are

reducing costs in green ammonia production.

Key Strategies for Cost Reduction in Green Ammonia Production

- Scaling Up Electrolysis

Electrolysis, the process used to produce green hydrogen, is currently one of the most significant cost

drivers. Electrolyzers are expensive, and at present, they operate at relatively low efficiencies. To

reduce costs, several strategies are being employed:

Increase Production Scale: Building larger electrolyzers can bring down the cost of production

by benefiting from economies of scale. Larger facilities can produce more hydrogen at a lower

cost per unit.

Technological Advancements: Research and development into more efficient electrolyzer

technologies, such as solid oxide electrolyzers (SOECs) and proton exchange membrane (PEM)

electrolyzers, promise to reduce energy consumption and improve efficiency.

Utilization of Low-Cost Renewable Energy: Countries with abundant wind and solar

resources are integrating electrolyzers with these energy sources, ensuring that hydrogen

production is cost-effective and powered by cheap renewable electricity. - Optimizing Renewable Energy Integration

The cost of electricity is another key factor in the production of green hydrogen and thus green

ammonia. To reduce this cost, producers are looking for ways to optimize renewable energy use:

Energy Storage Systems: Renewable energy is intermittent, which leads to fluctuations in

production. The integration of energy storage systems, such as batteries or thermal storage,

helps stabilize the supply of energy, reducing downtime for electrolyzers and ensuring

consistent hydrogen production.

Hybrid Energy Systems: Using a mix of renewable energy sources like solar, wind, and even

hydro, to power green hydrogen production plants reduces the dependence on a single type

of energy, thereby lowering costs and improving reliability. - Geographic and Industrial Synergies

Location and the integration of ammonia production with existing industrial infrastructure can

dramatically reduce costs:

Proximity to Renewable Resources: Building ammonia plants near regions rich in renewable

energy resources reduces transmission costs. Countries like Australia and Chile, with

abundant solar and wind energy, are leading the way in this area.

Co-location with Fertilizer or Industrial Hubs: Co-locating green ammonia plants with existing

fertilizer production or chemical plants allows for shared infrastructure, reducing capital and

operational expenditures. This can also streamline the logistics of ammonia distribution. - Policy Support and Carbon Pricing

Governments are playing an important role in reducing the cost of green ammonia through:

Subsidies and Grants: Financial incentives such as subsidies for renewable energy projects or

grants for green hydrogen research are helping bring down production costs.

Case Study 1: Australia’s AREH – Leveraging Renewable Energy for Cost Efficiency

The Asian Renewable Energy Hub (AREH) in Australia is a prime example of reducing costs through

geographic synergies and energy optimization. The project leverages Australia’s vast, low-cost

renewable energy resources to drive down electricity costs for hydrogen production.

Strategies Used:

Gigawatt-Scale Production: By producing hydrogen and green ammonia at a massive scale

(up to 26 GW), AREH benefits from economies of scale, reducing the cost per ton of green

ammonia.

Energy Efficiency: The integration of both solar and wind energy allows for a more consistent

energy supply, minimizing downtime and reducing the variability in production costs.

Impact:

AREH aims to become a global green ammonia exporter, supplying markets like Japan and

South Korea where demand for low-carbon fuels is increasing, allowing for higher profits and

larger production volumes that further drive down costs.

Case Study 2: Norway’s Yara – Hybridizing Ammonia Production

Yara, a global fertilizer company based in Norway, is working on decarbonizing its ammonia

production by integrating green hydrogen into its production processes. The company operates one

of the world’s largest ammonia production plants and is experimenting with hybrid models that

combine traditional and green hydrogen.

Strategies Used:

Utilizing Existing Infrastructure: Yara is leveraging its existing ammonia synthesis

infrastructure to integrate green hydrogen. This minimizes the need for new capital

expenditures.

Government Support: Yara has benefited from Norway’s favorable carbon pricing policy,

which incentivizes the production of low-carbon ammonia.

Impact:

By hybridizing its ammonia production, Yara has achieved significant cost reductions, allowing

for an easier transition from grey to green ammonia while maintaining profitability.

Case Study 3: Chile’s Green Ammonia Project – Policy-Driven Cost Reductions

Chile’s Atacama Desert provides some of the world’s best solar irradiance, making it an ideal location

for green hydrogen production. The government has actively supported green ammonia projects

through policies and investments, including tax incentives and renewable energy subsidies.

Strategies Used:

Low-Cost Renewable Energy: By building plants in regions with abundant, cheap solar energy,

Chilean producers can dramatically reduce electricity costs.

Government Incentives: Chile has implemented policies that lower the tax burden for

renewable energy projects and provide grants for early-stage development.

Impact:

These strategies have led to a sharp reduction in the projected costs of green ammonia

production in Chile, positioning it as a future leader in the global green ammonia market.

In the next blog, we will dive into the market adoption strategies and explore the challenges and

breakthroughs surrounding green ammonia production on an industrial scale.

— Feel free to leave your comments or questions below. Stay tuned for more insights into the future

of green energy