Feasibility Studies

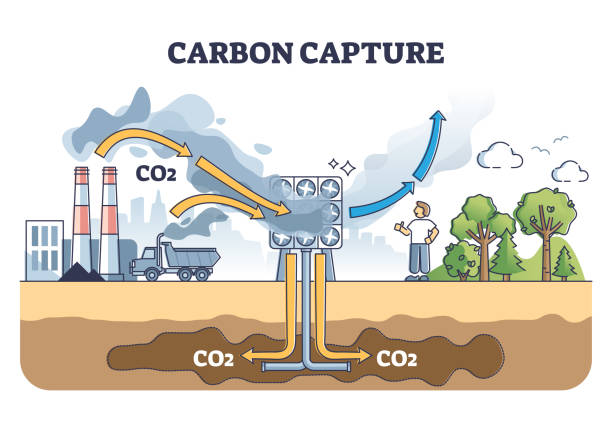

Our feasibility studies provide a thorough analysis to evaluate the potential of your carbon capture project.

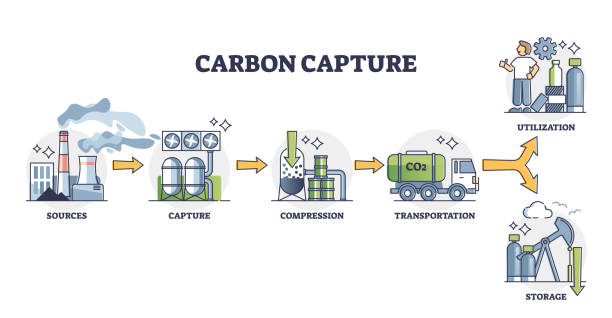

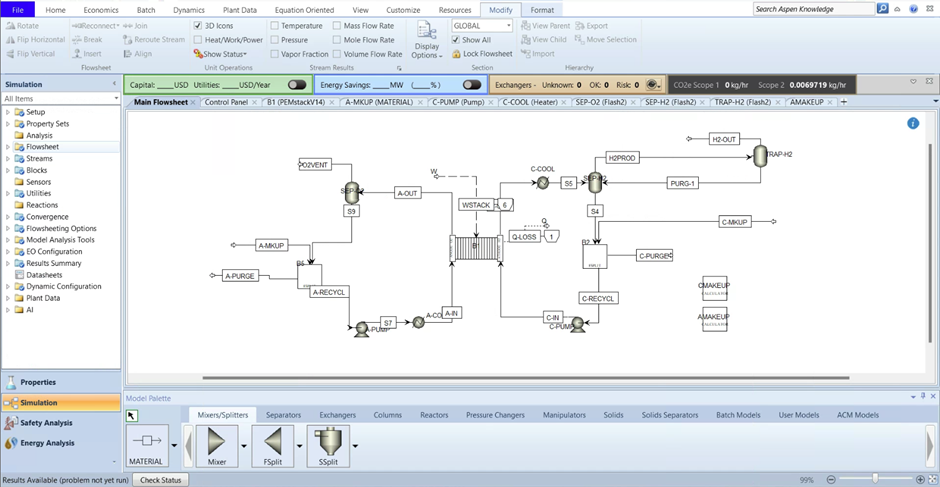

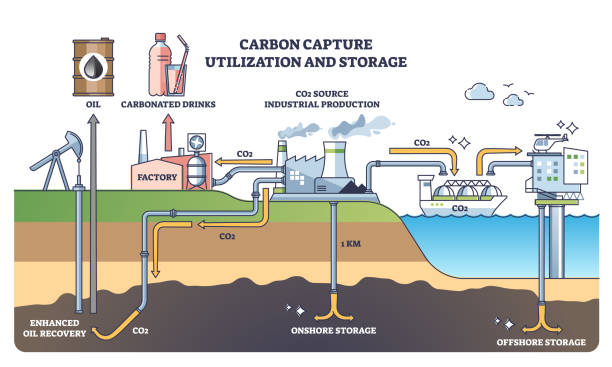

Assessment of Technical Feasibility: We analyze site-specific parameters, feed gas compositions, and operational constraints to determine the suitability of different carbon capture technologies.

Economic Evaluation: Detailed cost analysis, including CAPEX and OPEX, to ensure the project aligns with your financial objectives.

Environmental Impact Analysis: Evaluation of carbon capture systems’ contribution to emission reductions and compliance with environmental regulations.

Risk Assessment: Identification of technical and operational risks with mitigation strategies to ensure project reliability.