Storage and Transportation Challenges for Green Hydrogen: A Process Engineering Outlook

Introduction

While the discourse around green hydrogen as a vector for industrial decarbonization is gaining critical mass, the technical feasibility of its widespread deployment hinges on solving one of its most formidable bottlenecks—safe, efficient, and scalable storage and transportation. Unlike conventional hydrocarbons, hydrogen’s physicochemical properties—notably its low volumetric energy density and high diffusivity—impose profound engineering, infrastructural, and economic constraints.

The process engineer, therefore, plays a pivotal role in designing and evaluating systems that transcend thermodynamic feasibility to encompass material science, safety protocols, dynamic behavior modeling, and life-cycle cost analysis.

Thermodynamic and Material Challenges

At ambient conditions, hydrogen gas has an energy density of only ~3 kWh/m³, necessitating either compression to 350–700 bar, liquefaction at -253°C, or conversion to chemical carriers such as ammonia (NH₃) or methanol for economically viable transport. Each pathway entails its own set of technical trade-offs:

- Compressed Hydrogen Storage involves high-strength composite cylinders, pressure swing adsorption (PSA) systems, and complex control strategies for thermal management during charging and discharging cycles.

- Liquid Hydrogen Storage mandates cryogenic insulation, active boil-off gas (BOG) recovery systems, and is susceptible to latent heat-induced vaporization losses, often exceeding 0.3% per day.

- Hydrogen Carriers such as ammonia and LOHCs (liquid organic hydrogen carriers) require process simulation models for dehydrogenation kinetics, heat integration, and impurity handling to ensure reversibility and energy efficiency.

Infrastructure and Transportation Limitations

According to the International Energy Agency (IEA), global hydrogen transport infrastructure remains in its infancy, with fewer than 5,000 km of hydrogen pipelines in operation globally—primarily in industrial clusters across the US, Europe, and Japan. For comparison, the global natural gas pipeline length exceeds 3 million kilometers.

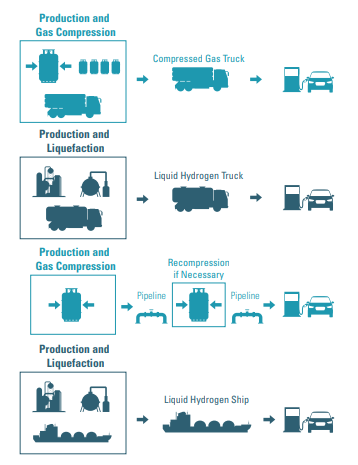

Key transportation modes under evaluation include:

- Pipeline Transport

Requires retrofitting or repurposing of existing natural gas networks. However, hydrogen embrittlement, caused by atomic hydrogen diffusion into steel grain boundaries, necessitates detailed fracture mechanics assessments and selection of low-carbon steels or polymer linings.

- Tube Trailers and ISO Containers

Used for short-distance high-pressure transport (up to 900 bar). They present challenges in payload efficiency and are economically unsustainable for large-scale supply chains.

- Maritime Shipping of Hydrogen Derivatives

Particularly promising for intercontinental trade, ammonia and methanol can leverage existing port and bunkering infrastructure. However, reconversion back to hydrogen involves energy penalties exceeding 30%, which must be accounted for in full-cycle simulations.

Current Industry Landscape

As of 2025, several notable developments have materialized:

- HyNet (UK) and Hydrogen Backbone Projects (EU) are exploring the repurposing of gas pipelines with advanced material coating strategies.

- Japan’s Suiso Frontier, the world’s first liquefied hydrogen carrier, completed its maiden voyage, symbolizing a nascent maritime hydrogen trade framework.

- India’s National Green Hydrogen Mission (2023) envisions a 5 MMT annual green hydrogen production capacity by 2030, with policy push towards infrastructure creation via viability gap funding and CAPEX incentives.

Nonetheless, a 2024 report by BloombergNEF underscores that storage and transport may account for up to 40% of delivered green hydrogen cost, underscoring the urgency of innovation in this domain.

The Role of Simulation and ChemKlub’s Expertise

At ChemKlub, we recognize that the design of robust hydrogen logistics systems must go beyond conventional process design. Our advanced programs enable professionals to:

- Model hydrogen liquefaction cycles, storage dynamics, and thermophysical behavior in Aspen HYSYS® and Aspen Plus®.

- Evaluate dehydrogenation and reformation loops for carriers like ammonia and methanol.

- Simulate multi-modal transport networks, integrating techno-economic and safety risk analyses.

With expert-led guidance and hands-on case studies, ChemKlub ensures that process engineers are equipped to handle the multifaceted challenges of hydrogen logistics, from micro-scale vessel design to macro-scale supply chain optimization.

Conclusion

The transition to a hydrogen economy will be constrained not by its chemistry but by our capacity to engineer storage and transport solutions that are safe, cost-effective, and scalable. From cryogenic vessels to chemical loops and digital twins, the future of green hydrogen logistics will be engineered—not imagined.

Let ChemKlub be your partner in developing those solutions.