Building a Dynamic Digital Twin: Key Data and Simulation Needs

The modern chemical plant operates in a highly dynamic environment—one where product quality, process safety, and asset integrity depend on the ability to observe and react to changing conditions in real time. This is where Dynamic Digital Twins (DDTs) provide strategic value.

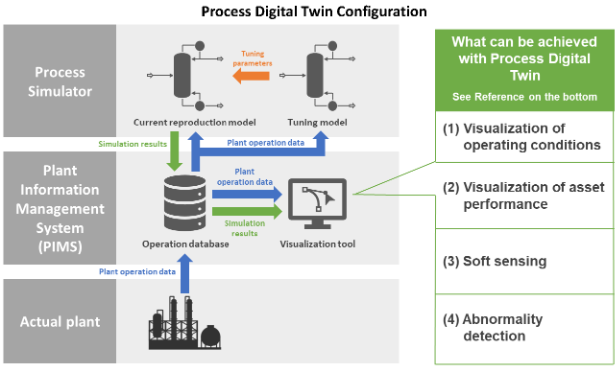

Unlike static simulation models or offline analytics, a DDT provides a continuously updating representation of a physical system by integrating live data, physics-based modeling, and predictive algorithms. Building such a system requires careful planning of both the data infrastructure and simulation frameworks. This post outlines the key technical considerations for implementing a dynamic digital twin in a chemical processing environment.

🏗️ 1. Digital Twin Architecture for Chemical Plants

A chemical plant’s DDT framework must support both continuous and batch operations, high-speed data capture, and complex model integration.

🔌 Data Acquisition Layer

- Instrumentation: Flow transmitters, differential pressure sensors, thermocouples, chromatographs, FTIR/GC analyzers.

- ISA-88/95-compliant PLC/DCS systems.

- Edge computing units to preprocess data (e.g., spike removal, moving average, deadband filtering).

🧵 Communication & Integration Layer

- OPC-UA and MQTT brokers for standardized messaging.

- Time-synchronized data buses using Apache Kafka, PI System, or Azure IoT Hub.

- REST/GraphQL APIs for system interconnectivity.

📁 2. Data Requirements: What a Chemical Plant Needs to Feed the Twin

Creating a dynamic twin requires granular, validated, and timestamped data from several domains:

🛠️ Static Engineering & Design Data

- PFDs, P&IDs, instrumentation data sheets.

- Heat and material balance from Aspen Plus/HYSYS models.

- Equipment datasheets (agitators, reactors, centrifuges, scrubbers, etc.)

🧾 Historical Operations Data

- Batch records from MES systems (ISA-88 Batch Execution).

- Historian data: Reactant feed profiles, temperature ramps, phase hold times.

- Alarm logs, trip records, and manual operator interventions.

📈 Real-Time Process Data

- Continuous measurements: reactor jacket temperature, distillation column reflux ratios, level control data.

- Analyzer feedback for QA/QC (product purity, conversion %, pH, etc.)

- Operator setpoints and valve positions.

🌍 External and Environmental Data

- Ambient temperature, humidity, and feedstock variability (e.g., purity levels, BTX content).

- Utility data (steam pressure, cooling water temperature) and energy costs.

🔬 3. Simulation Models for Chemical Processes

⚗️ Physics-Based (First-Principles) Models

These models are indispensable for simulating reaction kinetics, mass transfer, and thermodynamics.

🧪 Process Simulation

- Tools: Aspen HYSYS Dynamics, gPROMS, Dymola

- Use for simulating:

- Exothermic reactor dynamics (e.g., CSTR, PFR)

- Distillation columns (multi-stage equilibrium or rate-based models)

- Heat exchanger networks (HEN)

🔄 Equipment Simulation

- Agitated reactors: incorporate mixing profiles, residence time distribution (RTD)

- Centrifuges: torque-speed behavior under fouling conditions

- Scrubbers: absorption kinetics and pressure drop models

Fluid Flow and Transport

- Multiphase flow models for gas-liquid separators

- Compressible vapor flow in relief systems (use API 520/521 calculations)

- CFD for modeling velocity and temperature profiles in reactors and furnaces

📊 Data-Driven & Hybrid Models

🔍 Soft Sensors & Virtual Analyzers

- Regressors (PLS, SVR, Lasso) trained on lab data for real-time purity or viscosity prediction.

🤖 Machine Learning Models

- Predict fouling in heat exchangers using historical inlet/outlet temperature and ΔP

- Use classification models to detect abnormal states in polymerization or crystallization

- Forecasting product yield using time-series neural networks (LSTM, GRU)

🧠 Hybrid Models

- PINNs (Physics-Informed Neural Networks) for complex kinetic systems

- Use ML models to adjust empirical correlations (e.g., correction factors in VLE calculations)

🔄 4. Model Integration and Synchronization

🔧 Model Coupling and Co-Simulation

- Use FMI standards to co-simulate:

- Aspen model with MATLAB controllers

- gPROMS model with custom Python scripts for ML

📡 Real-Time Model Updating

- Extended Kalman Filters (EKF) for continuous state estimation in reactors

- Adaptive parameter tuning for reaction kinetics and heat transfer coefficients

📊 Uncertainty Quantification

- Monte Carlo simulations with variable purity, catalyst activity

- Propagation of sensor noise in concentration control loops

☁️ 5. IT Infrastructure for Chemical Plant Twins

🧱 Edge + Cloud Deployment

- Edge: Run control-critical models like exothermic runaway prevention

- Cloud: Perform heavy analytics (e.g., ML retraining, optimization)

📚 Data Architecture

- Time-series DBs (PI System, InfluxDB) for sensor data

- Central data lake (Parquet on S3 or Azure Blob) for batch records and lab data

🧪 DevOps in Simulation

- CI/CD pipelines for model updates (Git + Docker + Jenkins)

- Version control for simulation models and configuration files

📊 6. Visualization and Decision Support

🔍 Dashboards

- Operator-focused: Real-time batch phase tracker, deviation indicators

- Engineering-focused: Fouling index, solvent recovery efficiency, energy usage

📈 Analytics

- Predict batch failures using early-stage indicators

- Optimize reflux/feed ratio in distillation columns to minimize energy use

⚠️ 7. Key Chemical Industry Challenges

| 🚧 Challenge | 🛠️ Solution |

| Batch variability | Use adaptive models + phase recognition via ML |

| Nonlinear kinetics | Use detailed reactor models with real-time tuning |

| Catalyst deactivation | Include fouling/deactivation models with age functions |

| Energy integration complexity | Digitally twin heat exchanger networks (HXN) |

🧠 Final Thoughts

In the chemical industry, dynamic digital twins can significantly boost process reliability, batch quality, and plant profitability. The integration of engineering design, real-time operational data, and predictive simulations provides a comprehensive, living mirror of your physical system.

By capturing everything from catalyst behavior to solvent recovery, a well-architected DDT enables chemical engineers to make decisions with confidence—long before problems manifest in the plant.