Integrating AspenTech, AVEVA and Siemens Platforms in Digital Twin Solutions

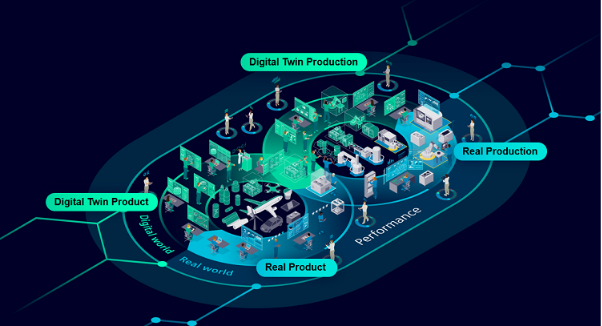

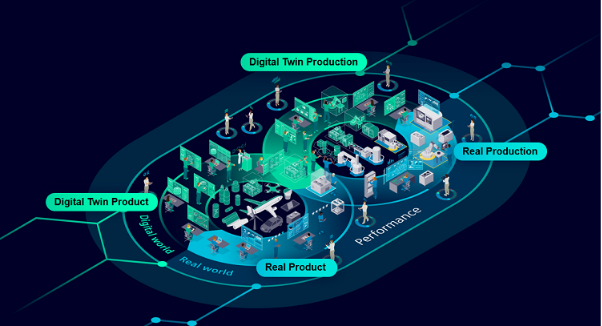

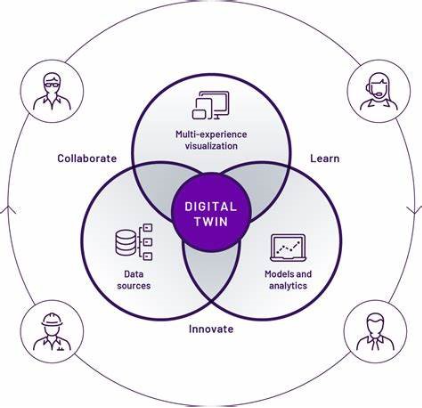

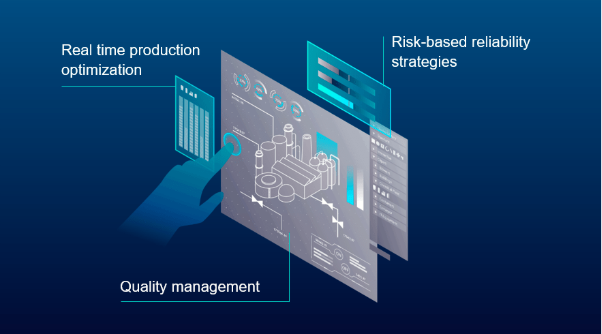

As industries push toward greater efficiency, safety, and sustainability, Digital Twin technology has become a cornerstone of industrial innovation. Among the key players in this transformation are AspenTech, AVEVA, and Siemens—each offering specialized software platforms that serve different aspects of asset and process performance. Integrating these platforms into a cohesive digital twin architecture unlocks a new level of operational excellence.

Understanding the Core Platforms

AspenTech specializes in process simulation, asset performance management, and advanced analytics. It provides powerful tools like Aspen HYSYS and Aspen Plus for process modeling and simulation.

AVEVA offers a broad suite of engineering and operations solutions, including AVEVA E3D for 3D design, AVEVA PI System for data aggregation, and AVEVA Unified Operations Center for centralized monitoring.

Siemens contributes through platforms like COMOS for plant engineering, Simatic PCS 7 for process control, and Siemens NX for product lifecycle management (PLM).

Each of these platforms brings specific strengths, but when integrated, they provide a comprehensive digital twin that spans design, operations, and optimization.

The Need for Integration

Digital twin solutions require the convergence of:

- Engineering data (P&IDs, 3D models, instrumentation)

- Operational data (real-time sensor data, control systems)

- Simulation models (steady-state and dynamic behavior)

No single vendor offers a complete solution. Integration allows for:

- Data consistency across systems

- Improved collaboration among departments

- Automated updates and version control

- Enhanced simulation accuracy using real-time data

Key Integration Strategies

1. Data Standardization and Interoperability

Using open standards such as OPC UA, ISO 15926, and AutomationML enables data exchange across platforms. These standards ensure that AspenTech models can communicate with AVEVA’s operational data and Siemens’ control systems without proprietary barriers.

2. Middleware and APIs

Custom APIs and middleware solutions allow platforms to interconnect. For instance:

- Aspen HYSYS can be connected to real-time process data via AVEVA PI System.

- Siemens’ COMOS database can be synchronized with AVEVA’s design tools through API connectors.

- Simulation results from AspenTech can inform control strategies implemented in Siemens PCS 7.

3. Cloud and Edge Integration

Leveraging cloud platforms enables scalable digital twins. Siemens MindSphere, AVEVA Connect, and AspenTech Inmation can host digital twins in the cloud, allowing remote access, analytics, and updates.

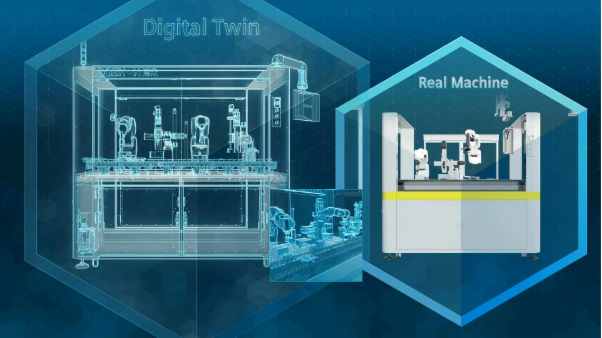

4. Dynamic Simulation with Real-Time Feedback

By integrating AspenTech’s dynamic simulation with live data from AVEVA PI and Siemens PLCs, users can perform predictive simulations, validate control logic, and test scenarios in a safe virtual environment.

Benefits of a Unified Digital Twin Ecosystem

- Real-time monitoring and forecasting

- Reduced downtime through predictive maintenance

- Streamlined engineering workflows

- Improved compliance and safety analysis

- Faster commissioning and operator training

For example, a chemical plant can design its process in AspenTech, build the 3D environment in AVEVA E3D, and run the operation using Siemens PCS 7. A unified digital twin integrates all these layers, ensuring accurate performance tracking and seamless updates from design changes to operational tweaks.

Challenges and Considerations

While integration offers immense value, challenges such as data silos, vendor lock-in, and interoperability issues must be addressed. Companies need:

- Strong IT/OT alignment

- Data governance policies

- Skilled personnel familiar with multiple platforms

Investing in systems integrators or digital twin consultants may be beneficial for complex projects.

| Challenge | Solution |

| Data interoperability | Use of open standards like OPC UA and ISA-95 |

| Model accuracy | Continuous calibration using live data |

| Cybersecurity | Segmented networks and secure data gateways |

| Scalability | Cloud-native solutions and containerization |

Conclusion

Integrating AspenTech, AVEVA, and Siemens platforms creates a powerful foundation for building high-fidelity, real-time digital twins. This collaboration enables industries to not only visualize their processes but actively optimize them, reduce risks, and accelerate digital transformation. As technology continues to evolve, the synergy between these platforms will define the next frontier of intelligent industrial systems.