Feasibility Studies & Conceptual Design

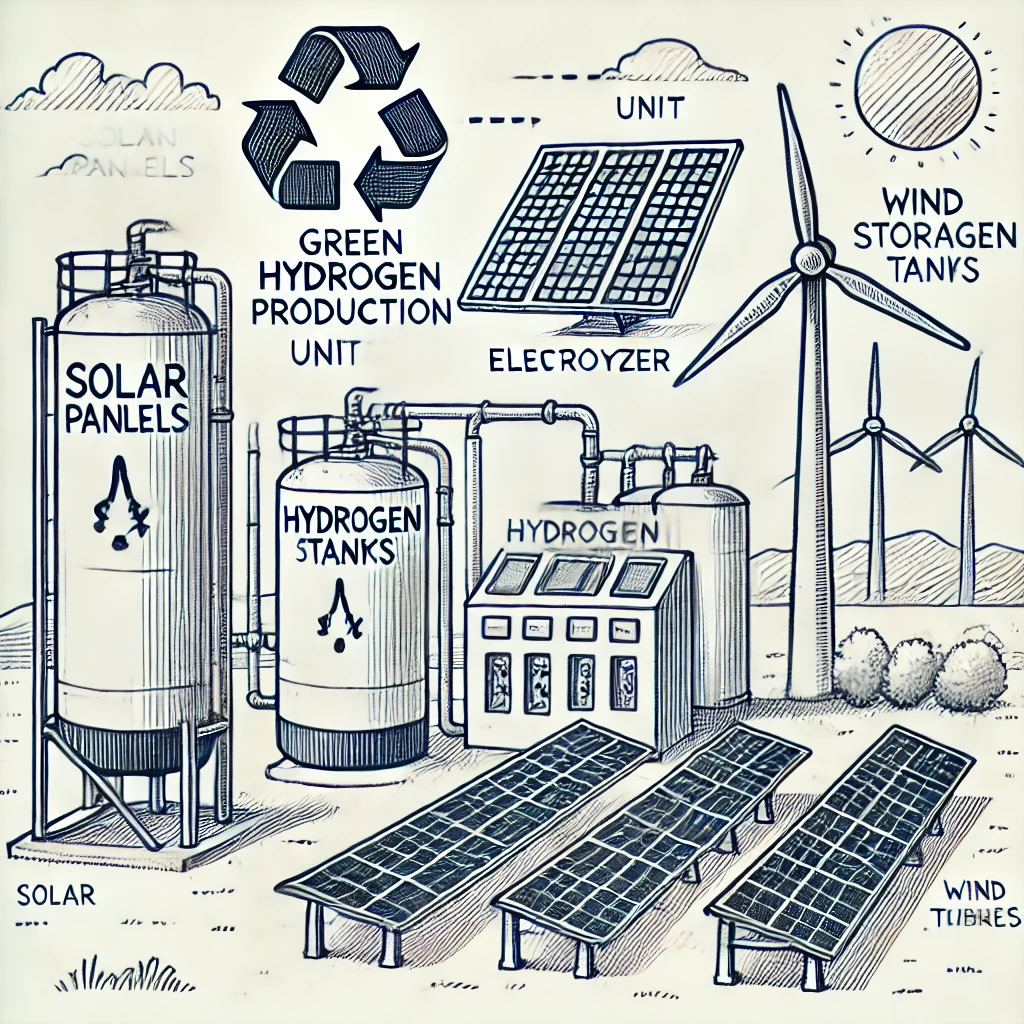

Assessment of renewable energy sources (solar, wind, hydropower) for green hydrogen production.

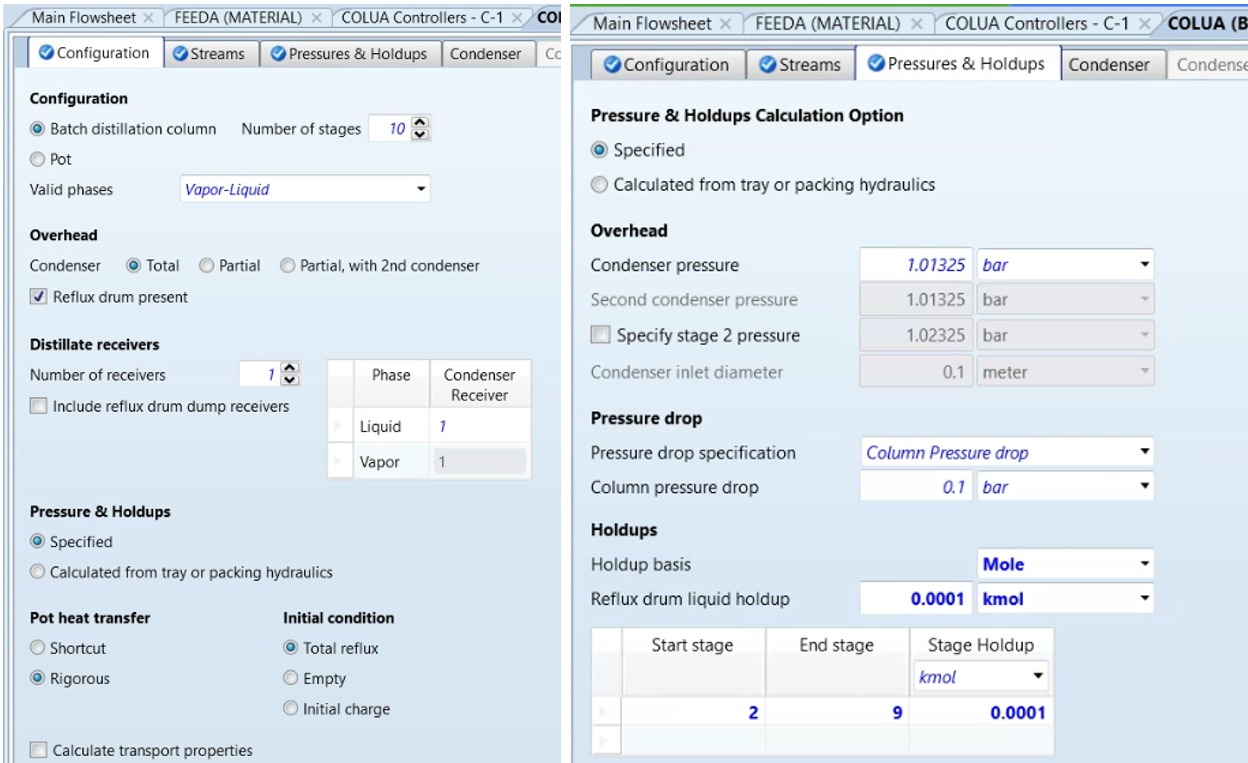

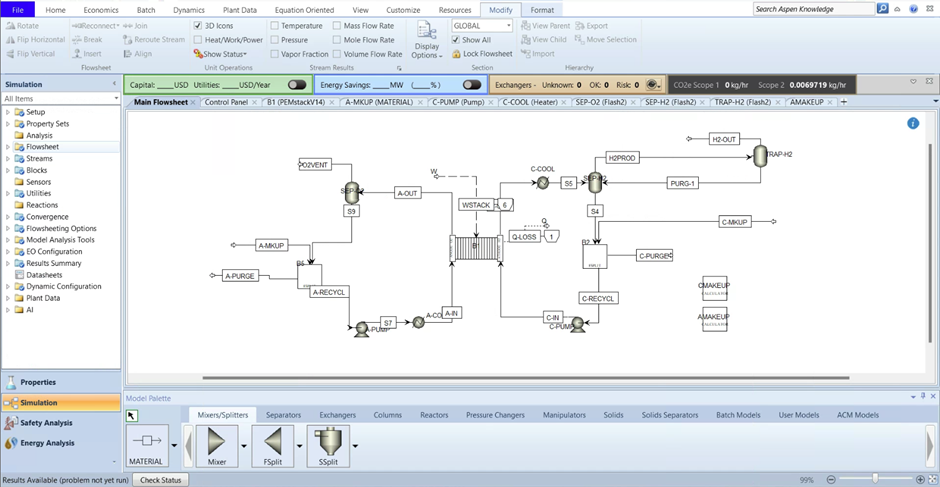

Techno-economic analysis of electrolyzer technologies (PEM, Alkaline, and Solid Oxide Electrolysis).

Site selection and infrastructure assessment for optimal hydrogen production facilities.