Driving the Future of Energy: Modeling Green Hydrogen Production Using Aspen Plus and Alkaline Electrolyzers

As the global energy landscape undergoes a profound transformation, green hydrogen is emerging as a cornerstone of the sustainable energy transition. With its potential to decarbonize sectors ranging from transportation to heavy industry, green hydrogen represents a powerful solution for achieving net-zero emissions. Central to this process is the electrolyzer, a technology that converts water into hydrogen using renewable electricity. Among the different electrolyzer types, the alkaline electrolyzer stands out for its cost-effectiveness, scalability, and industrial maturity.

In this post, we explore how Aspen Plus, a leading process simulation tool, can be leveraged to model and optimize green hydrogen production using an alkaline electrolyzer. To illustrate, we’ll also present a case study that demonstrates real-world application.

Unlocking the Potential of Alkaline Electrolyzers

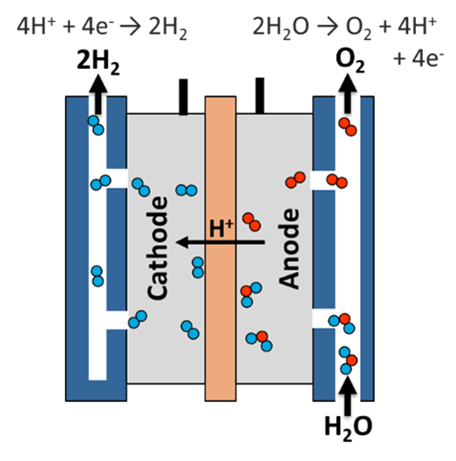

Alkaline electrolysis is a well-established technology that utilizes an alkaline solution, typically potassium hydroxide (KOH) or sodium hydroxide (NaOH), as the electrolyte to split water into hydrogen and oxygen. The simplicity, durability, and scalability of alkaline electrolyzers make them ideal for large-scale green hydrogen production, particularly in industries where cost-effectiveness is paramount.

Simulating Green Hydrogen Production with Aspen Plus

Aspen Plus offers a robust platform for modeling complex chemical processes, making it an invaluable tool for optimizing green hydrogen production. Here’s how you can model this process:

- Process Setup: Begin by configuring a process flow diagram (PFD) that includes water and electricity as feed streams, an electrolyzer unit, and downstream separation units for hydrogen and oxygen.

- Thermodynamics: Choose the appropriate thermodynamic models, such as NRTL or activity coefficient models, to accurately represent electrolyte behavior.

- Optimization: Fine-tune key operating parameters—like temperature, pressure, and electrolyte concentration—to maximize hydrogen output while minimizing energy consumption.

Case Study: Optimizing Green Hydrogen Production for an Industrial Plant

Background: A chemical plant in India aimed to integrate green hydrogen production into its operations to support its sustainability goals. The plant planned to use an alkaline electrolyzer powered by renewable energy to produce hydrogen for its ammonia synthesis process.

Simulation Setup: Using Aspen Plus, the engineering team modeled the green hydrogen production process, focusing on the following parameters:

- Feedstock: Deionized water with a flow rate of 100 kg/hr.

- Electrolyzer Specifications: Operating at 80°C and 30 bar with a KOH concentration of 30%.

- Power Supply: Renewable electricity input of 1 MW.

Optimization and Results:

- Hydrogen Production Rate: The simulation predicted a hydrogen production rate of approximately 20 kg/hr.

- Energy Efficiency: The specific energy consumption was optimized to 50 kWh/kg of hydrogen, which is competitive with industry benchmarks.

- Operational Insights: The team identified that increasing the operating temperature slightly improved the hydrogen production rate but required careful management of electrolyte concentration to avoid degradation.

Outcome: The optimized process design was implemented, leading to a successful integration of green hydrogen production into the plant’s operations. The plant reported a 15% reduction in carbon emissions and a 10% cost savings in ammonia production, demonstrating the economic and environmental benefits of adopting green hydrogen technology.

Gleaning Insights from Simulation Results

The power of Aspen Plus lies in its ability to simulate real-world processes with precision. By analyzing the hydrogen production rate, specific energy consumption, and comparing these metrics with industry standards, engineers can identify opportunities to improve efficiency and reduce costs. This kind of optimization is crucial as industries seek to scale up green hydrogen production to meet growing demand.

Why This Matters for Industry

Alkaline electrolyzers are already in use across various sectors, including ammonia production, oil refining, and power-to-gas applications. The ability to model these systems in Aspen Plus not only enhances design accuracy but also supports the development of more efficient and scalable hydrogen production facilities. As the global push for clean energy intensifies, mastering such simulations is essential for driving innovation and staying ahead in the energy transition.

Conclusion: Pioneering the Path to Sustainability

Green hydrogen is more than just a buzzword; it’s a critical component of a sustainable energy future. By leveraging advanced tools like Aspen Plus to model and optimize hydrogen production, we can accelerate the adoption of this clean energy carrier and contribute to a greener, more resilient world.

Let’s continue to explore, innovate, and lead the charge towards a hydrogen-powered future.

🔗 Follow ChemKlub India https://www.linkedin.com/company/72165041/admin/dashboard/and connect with us for more insights and updates on sustainability and the latest advancements in green technologies. Together, we can drive the change towards a sustainable and energy-efficient world.