Harnessing Green Hydrogen for a Sustainable Future – The Role of Aspen Plus and Aspen HYSYS in Enhancing Sustainability

Green hydrogen has emerged as a cornerstone of the global transition toward a sustainable energy future. As the cleanest form of hydrogen, produced through the electrolysis of water using renewable energy sources like wind and solar, green hydrogen offers a promising solution to decarbonize various sectors, including industry, transportation, and power generation. However, achieving widespread adoption of green hydrogen requires not just the right technology for production but also effective tools for optimizing and ensuring sustainability throughout the lifecycle of its production and use. This is where advanced process simulation software like Aspen Plus and Aspen HYSYS come into play.

The Growing Importance of Green Hydrogen

The drive towards sustainability has intensified in recent years, with governments and industries worldwide seeking to reduce their carbon footprints. Green hydrogen, with its potential to provide a zero-emission fuel, is a key player in this transition. It can be used directly as a fuel, as a feedstock in industrial processes, or as a means to store and transport renewable energy.

The global green hydrogen market is expected to grow exponentially, driven by policy incentives, technological advancements, and decreasing costs of renewable energy. However, the production and integration of green hydrogen into existing energy systems pose significant challenges, including efficiency optimization, cost reduction, and environmental impact minimization.

Aspen Plus: Optimizing Green Hydrogen Production

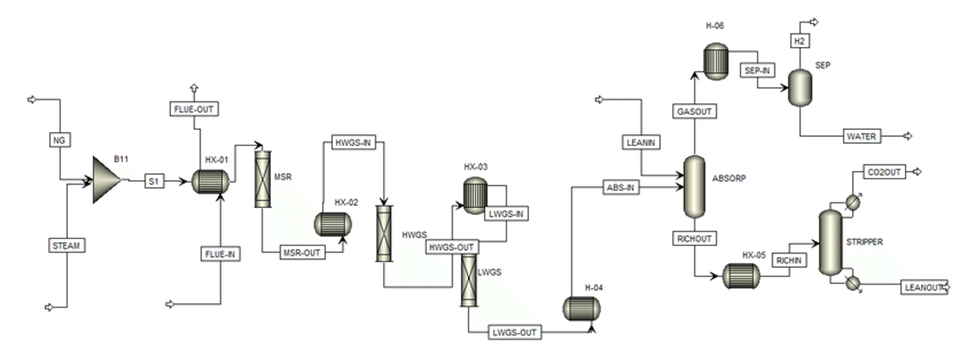

Aspen Plus, a powerful process simulation tool, plays a critical role in the optimization of green hydrogen production processes. It enables engineers and scientists to model, simulate, and optimize the entire hydrogen production chain, from the electrolyzer design to the integration with renewable energy sources.

- Process Modeling and Simulation: Aspen Plus allows for the detailed modeling of electrolyzers, considering various configurations and operating conditions. By simulating different scenarios, engineers can identify the most efficient and cost-effective setups, reducing energy consumption and increasing hydrogen yield.

- Process Optimization: Through advanced optimization techniques, Aspen Plus can help identify the optimal operating conditions that minimize energy use and maximize efficiency, ensuring that the green hydrogen produced is as sustainable as possible.

Aspen HYSYS: Enhancing Sustainability in Hydrogen Utilization

Aspen HYSYS, widely used for process simulation in the oil and gas industry, is equally vital in ensuring the sustainability of green hydrogen in downstream applications. It provides robust tools for simulating the integration of green hydrogen into existing systems and optimizing its use in various industrial processes.

- Process Integration: Aspen HYSYS enables the seamless integration of green hydrogen into existing industrial processes, such as refining and chemical production. By simulating the interactions between green hydrogen and other process streams, engineers can identify the best integration strategies that enhance overall system efficiency and reduce emissions.

- Dynamic Simulation: Aspen HYSYS supports dynamic simulation, which is crucial for modeling the transient behavior of processes involving green hydrogen. This is particularly important in scenarios where hydrogen production is coupled with intermittent renewable energy sources, ensuring that the entire system operates efficiently and sustainably under varying conditions.

- Energy Management: The software also facilitates energy management by simulating and optimizing energy flows within industrial processes. This includes the use of green hydrogen as a fuel or feedstock, helping to minimize energy losses and reduce the carbon footprint of the overall process.

Case Studies: Real-World Applications

Several industries have successfully leveraged Aspen Plus and Aspen HYSYS to enhance the sustainability of their green hydrogen projects.

Renewable Energy Integration: A leading renewable energy company used Aspen Plus to model and optimize the integration of green hydrogen production with a wind farm, achieving a 20% increase in efficiency and a 15% reduction in costs.

Industrial Decarbonization: A chemical manufacturer employed Aspen HYSYS to integrate green hydrogen into its ammonia production process, resulting in a 30% reduction in CO2 emissions and a significant decrease in energy consumption.

How ChemKlub Can Support

At ChemKlub India, we specialize in providing comprehensive technical consulting and process analytics services tailored to the green hydrogen sector. Our expertise in using Aspen Plus and Aspen HYSYS enables us to offer the following support:

Process Design and Optimization: We assist in modeling and optimizing green hydrogen production processes, ensuring maximum efficiency and sustainability.

Life Cycle Assessments: We conduct detailed environmental impact assessments to help identify the most sustainable production pathways.

Integration and Dynamic Simulation: We support the seamless integration of green hydrogen into existing industrial processes, leveraging our expertise in dynamic simulation to optimize energy management and reduce emissions.

By partnering with ChemKlub, industries can enhance their green hydrogen initiatives, ensuring they are both economically viable and environmentally responsible.