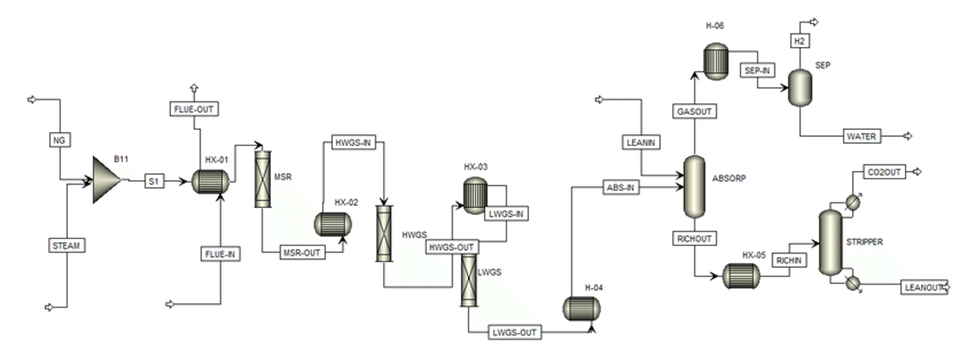

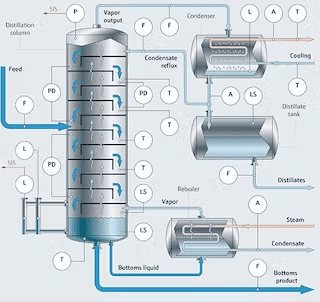

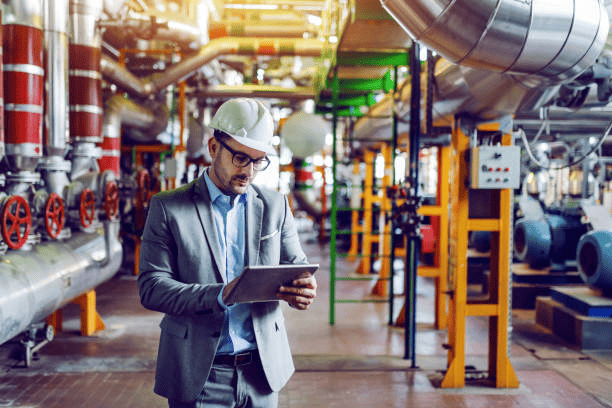

Process Development, Heat & Mass Balances

This service involves developing the overall process flow and ensuring that all material and energy flows are accurately accounted for. The Heat & Mass Balances are crucial for defining the inputs, outputs, and energy consumption at each stage of the process.

Benefits: Optimizes process design by providing key data for sizing equipment, determining energy requirements, and optimizing resource use.