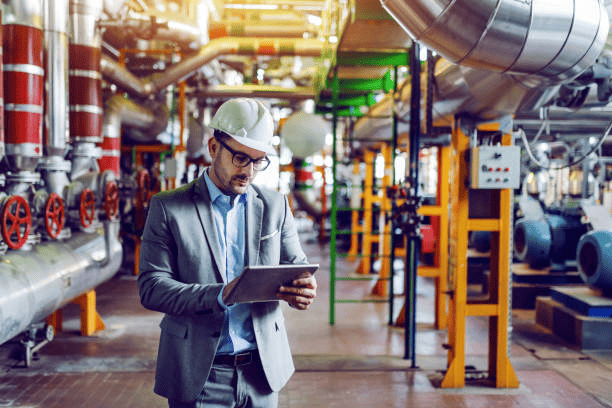

Process Engineering Capabilities

At ChemKlub India, our Process Engineering Consulting Services are designed to help clients optimize their operations, enhance safety, and ensure regulatory compliance. Our services span across industries like refineries, petrochemicals, specialty chemicals, and more. With a deep understanding of both traditional and advanced engineering methodologies, we provide innovative and tailored solutions for both greenfield and brownfield projects.

Process Design & Optimization

HAZOP Studies & Safety Analysis

Process Troubleshooting & Debottlenecking

Process Scale-Up Support

Basic & Detailed Engineering Packages

Energy Optimization

PSV & Flare System Design

Process Validation & Verification